In the grand machinery of modern civilization, from the silent flow of oil in deep-sea pipelines to the rhythmic pumping of a medical ventilator, there exists an invisible guardian: Pressure Detection. It serves as the nervous system for industrial safety, environmental monitoring, and scientific exploration, bridging the gap between fundamental physics and cutting-edge application.

1. The Core Principles

At its most elemental level, pressure detection is the translation of physical force into quantifiable data. The definition of pressure is deceptively simple: it is the vertical force applied per unit area.

P = F / S

Where P is pressure, F is the vertical force, and S is the area of application.

In engineering, a raw number is meaningless without a reference point. This necessitates the classification of pressure into three distinct categories:

Absolute Pressure: Measures pressure relative to a perfect vacuum. Indispensable in aerospace and deep-sea exploration.

Gauge Pressure: The difference between absolute pressure and local atmospheric pressure. This is what you see on a tire gauge.

Vacuum (Negative Pressure): Defines the state where absolute pressure is lower than local atmospheric pressure—critical for semiconductor manufacturing.

2. Detection Methodology

How do we measure the invisible? The evolution of pressure detection has branched into four primary methodological schools.

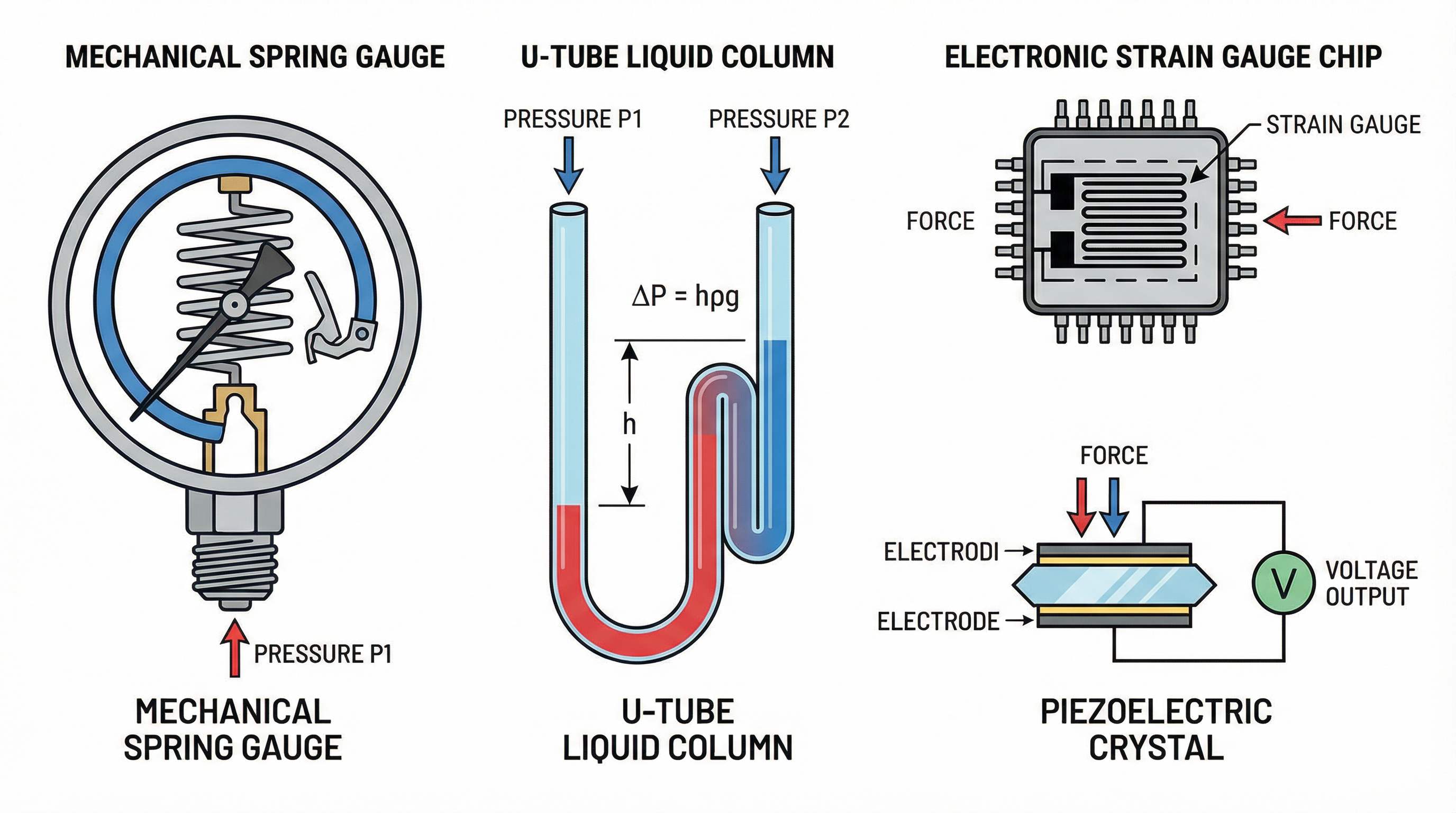

1. Mechanical Force Balance

Based on Hooke’s Law, elements like Bourdon tubes deform linearly under pressure. Ideal for local reading in rugged environments where power is unavailable.

2. Hydrostatic Equilibrium

Uses fluid statics in devices like U-tube manometers. While limited by height, they offer exceptional stability and serve as primary calibration standards.

3. Electrical Deformation

The standard for automation. Resistive Strain Gauges detect geometric changes, while Piezoresistive Sensors (semiconductors) detect atomic-level resistivity changes, offering 50-100x higher sensitivity.

4. The Piezoelectric Effect

Materials like quartz generate charge when stressed. Unrivaled for measuring dynamic changes like explosions or engine combustion, though useless for static pressure.

3. Typical Devices

The Bourdon Tube Pressure Gauge |

The Piezoresistive Pressure Sensor |

The Liquid Column Manometer |

4. Critical Application Scenarios

Pressure detection is not just about dials; it is about the safety and continuity of modern life.

Industrial Process Control: In chemical plants, piezoresistive sensors monitor reactors to prevent explosions. Distributed sensors in pipelines detect negative pressure waves to pinpoint leaks kilometers away.

Aerospace: Inside rocket combustion chambers, sensors endure 3000°C and 50 MPa. In cabins, aneroid sensors automatically deploy oxygen masks if depressurization occurs.

Medical Technology: Piezoelectric sensors in ventilators monitor airway pressure to prevent lung injury. Modern blood pressure cuffs use oscillometric sensors to detect tiny pulse fluctuations.

5. The Future Horizon

As we move deeper into Industry 4.0, pressure detection is evolving from passive measurement to active intelligence.

Smart Sensors & Edge Computing: Sensors now act as edge nodes, filtering noise and diagnosing issues locally.

The Wireless Revolution (IIoT): Low-power networks enable city-wide arrays where fire hydrants report pressure status in real-time.

Predictive Maintenance via AI: Algorithms analyze pressure "noise" to predict equipment failure weeks in advance.

Material Science: Graphene promises thinner, more flexible sensors for "electronic skin" applications.

Conclusion: Pressure detection serves as the bridge between the physical reality of forces and the digital world. From the deepest ocean trenches to the vacuum of space, our ability to explore and manufacture depends on our ability to measure P=F/S. As technology advances, these sensors will become smaller, smarter, and more integrated, silently ensuring the safety and efficiency of the world around us.