Safety valves (PSVs/PRVs) act as the ultimate line of defense for pressure vessels and piping systems. Their primary function is binary: to open automatically when pressure limits are exceeded and, crucially, to close (reseat) once conditions normalize. While opening reliability is paramount, the failure to reseat—known as Blowdown Failure or Stuck Open scenarios—poses severe operational risks, ranging from expensive media loss to catastrophic equipment shutdowns. This analysis dissects the mechanics of these failures and provides engineering solutions.

1. Sealing Failure: Direct Cause of Leakage

The integrity of a safety valve relies entirely on the precision fit between the disc (valve clack) and the nozzle (seat). Even microscopic imperfections in this interface can lead to significant failure. The primary contributors to sealing interface degradation include:

Mechanical Damage: Scratches, corrosion pits, or plastic deformation create bypass channels. High-velocity fluid can turn minor contaminants into projectiles.

Contamination: Soft deposits like oil, scale, or crystallizing media prevent metal-to-metal contact.

Material Degradation: In high-temperature environments, elastomeric O-rings may vitrify (harden and crack), while standard steels may suffer from intergranular corrosion.

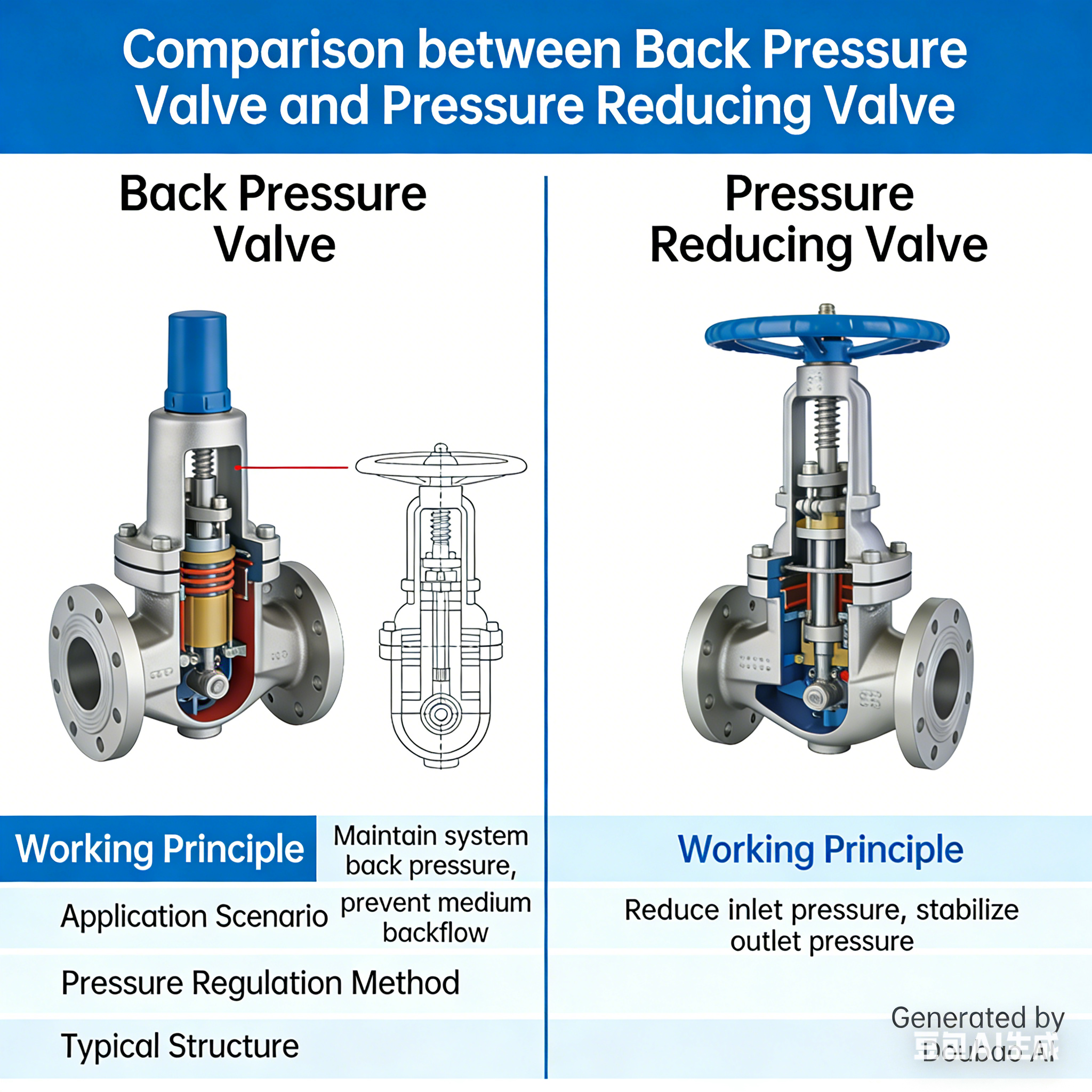

2. Back Pressure Interference: Dynamic Instability

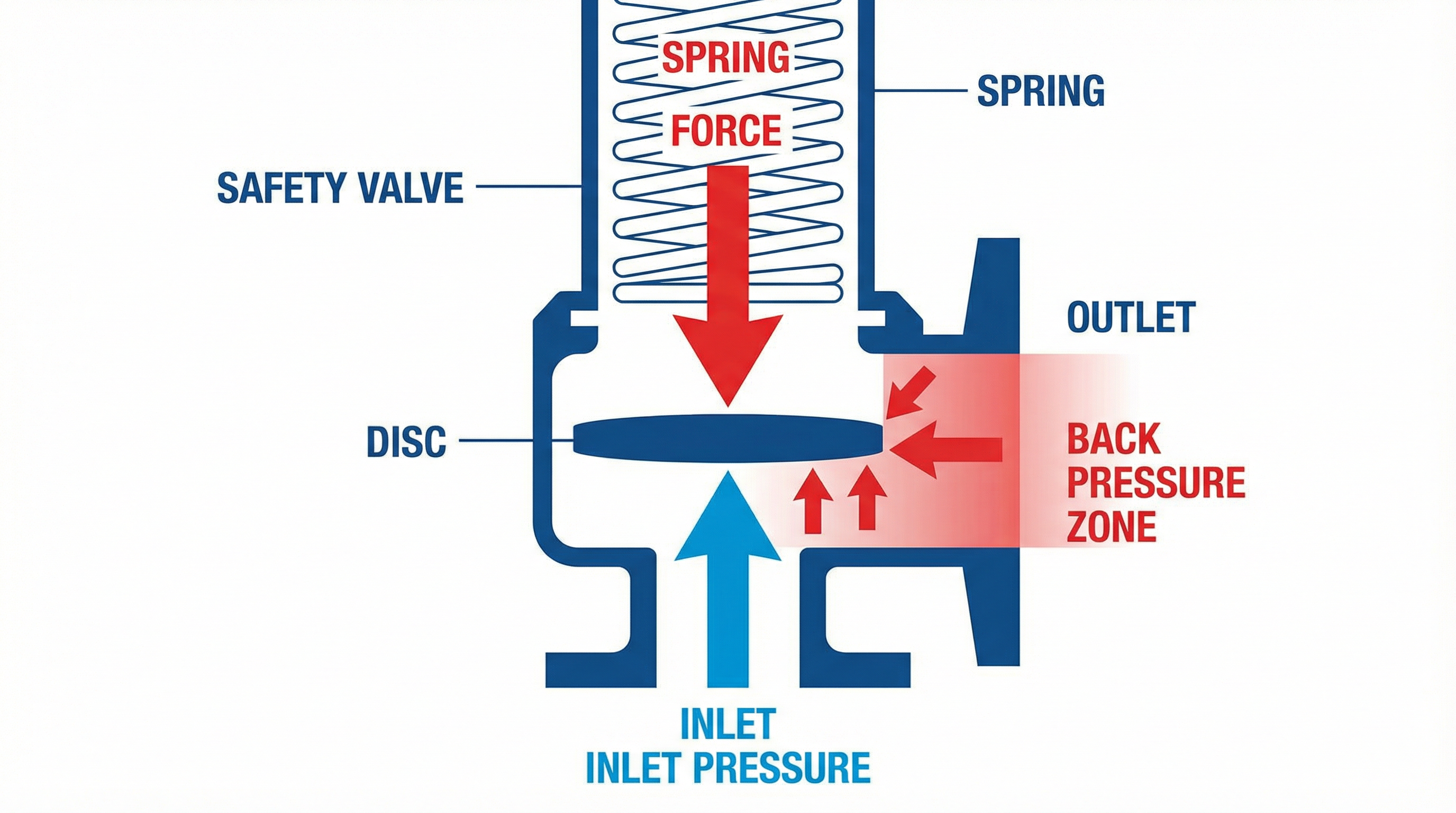

Safety valves operate on a delicate force balance. Back pressure—the pressure existing at the valve outlet—can significantly disrupt this balance.

"Back pressure acts as a variable force that typically opposes the spring, potentially preventing the valve from reseating until the system pressure drops significantly below the intended set point."

Accumulation of condensate in discharge headers or "built-up" back pressure from flow resistance can create hydrostatic heads. This variable force leads to instability and excessive blowdown. Engineering solutions include adjusting the Cold Differential Test Pressure (CDTP) for constant back pressure, or utilizing Balanced Bellows or Pilot-Operated valves for variable conditions.

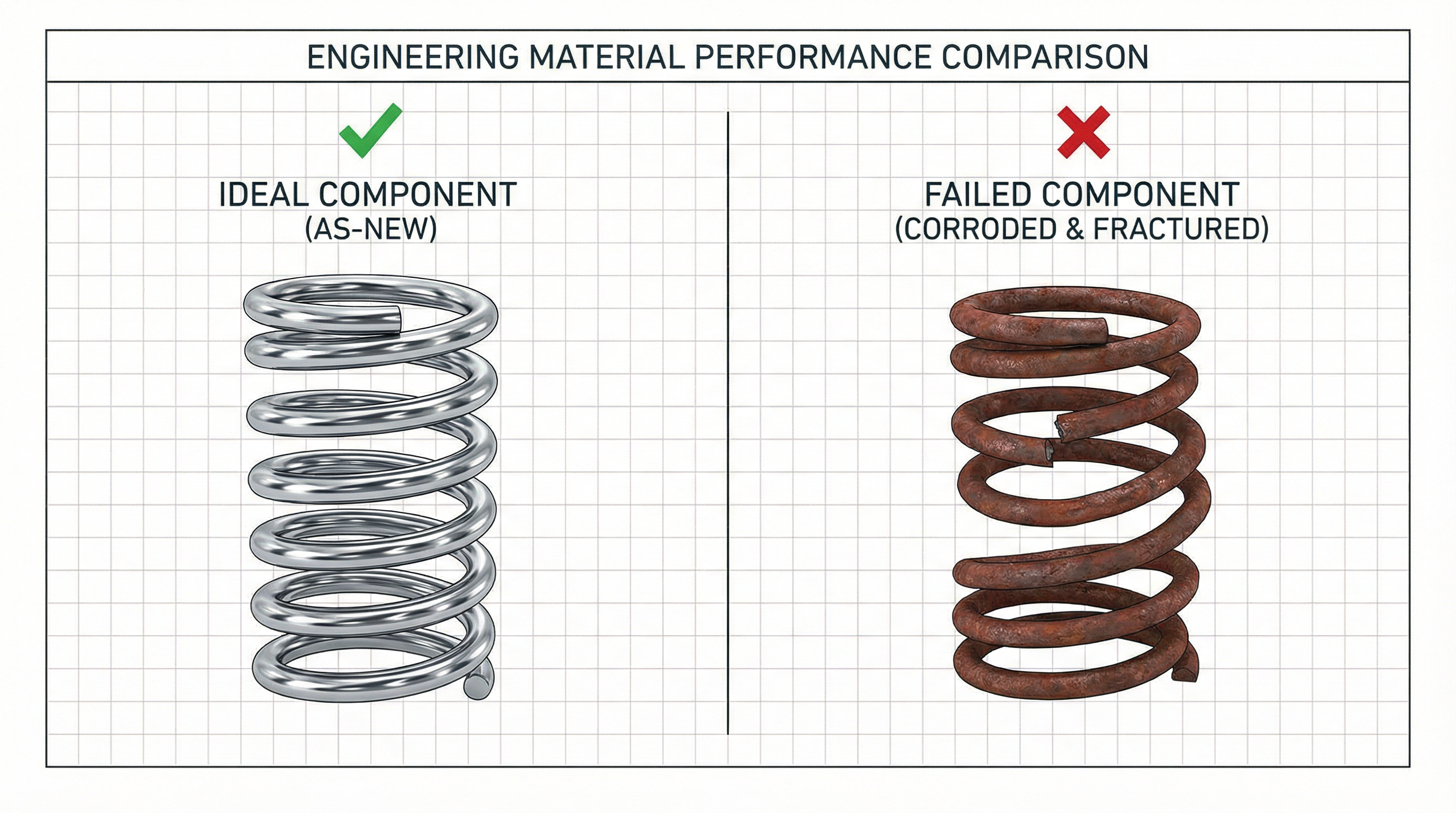

3. Structural Defects: Potential Risks in Design

Internal component failure often stems from long-term exposure to harsh process conditions. The spring, being the "heart" of a direct-acting safety valve, is particularly vulnerable to degradation:

Fatigue Fracture: Under cyclic loading, micro-cracks can propagate, leading to sudden failure.

Creep & Relaxation: At high temperatures (e.g., 450°C), metal grains slide, causing permanent deformation and a loss of closing force (Hooke’s law breakdown).

Corrosion Cracking: In chloride-rich environments, Stress Corrosion Cracking (SCC) reduces the effective wire diameter.

4. Improper Maintenance & Solutions

Even the best-engineered valve will fail without proper stewardship. API 527 and national regulations mandate regular testing, yet "run-to-failure" mentalities persist.

Calibration Strategy: Utilizing In-Situ (Online) Testing is a best practice. This employs hydraulic assist devices to verify set pressure without disrupting operations or subjecting sealing surfaces to the trauma of removal.

Discharge Piping: The piping downstream is part of the safety system. Excessive bends or narrow pipes create high resistance coefficients ($\zeta$), causing the valve to chatter. Retrofitting with long-radius elbows helps mitigate this issue.

Conclusion

The failure of a safety valve to reseat is rarely a single-point failure; it is usually a convergence of design limitations, material degradation, and environmental factors. Reliability cannot be inspected into a valve; it must be engineered into the system. Organizations must transition to Risk-Based Inspection (RBI) methodologies to ensure that when pressure rises, the safety valve performs its dual duty: to open for safety, and to close for continuity.