In industries demanding near-perfect cleanliness and sealing—such as semiconductor manufacturing, aerospace, nuclear energy, and medical applications—VCR fittings (Vacuum Coupling Radius Seal) have become indispensable “safety valves” in piping systems due to their unique design and exceptional performance. As a representative of metal-to-metal face seal couplings, VCR couplings achieve leak-free connections from vacuum to high-pressure environments through precision mechanical structures and material science. Their technological core and application value warrant in-depth analysis.

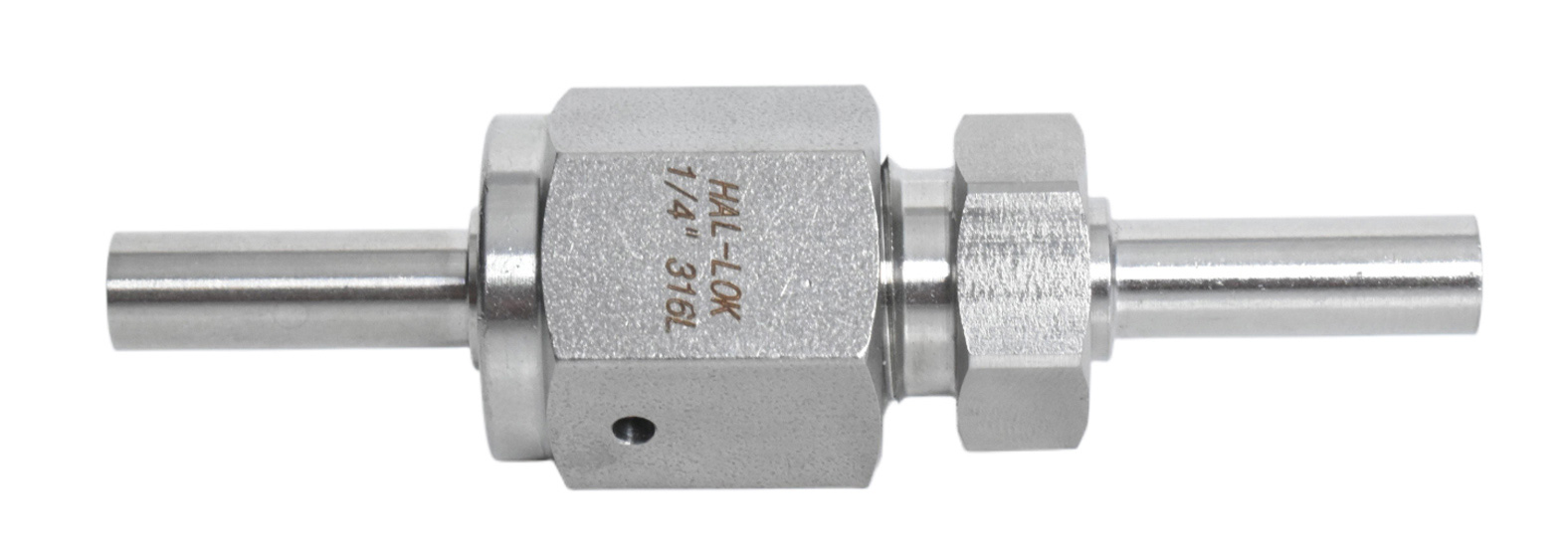

The core of VCR couplings lies in their face seal design. The fitting comprises an inner and outer threaded nut, a metal gasket, and connecting pipes. During installation, rotating the inner and outer threaded nuts progressively compresses the flanges at both ends against the metal gasket.

The gasket, made of high-purity stainless steel (e.g., 316L), nickel, or silver-plated copper, undergoes controlled deformation under pressure. This deformation fills microscopic irregularities on the contact surfaces, forming a hard metal-to-metal seal. This design not only withstands extreme environments ranging from vacuum (10⁻⁹ mbar) to high pressure (up to 690 bar) but also effectively prevents particulate contamination, meeting semiconductor-grade cleanliness requirements (surface roughness ≤0.2μm).

VCR fitting components undergo electropolishing and cleaning processes to prevent metal ion migration. In semiconductor manufacturing, this prevents contamination of chips via specialty gas delivery lines, ensuring stable etching processes. For example, in 12-inch fabs, imported VCR fittings maintain leakage rate fluctuations below 5%, guaranteeing 2000 trouble-free cycles in PFET/NFET etching tests.

High-Temperature Tolerance: VCR fittings with nickel gaskets maintain stable operation at 537°C, suitable for rocket engine fuel lines.

Vibration Resistance: Vibration-absorbing collars or locking mechanisms prevent seal failure, ensuring long-term operation in satellite vacuum chambers.

New gaskets are required after each disassembly, while nuts and fittings remain reusable, reducing maintenance costs. During semiconductor equipment maintenance, VCR fittings rapidly restore sealing performance, reducing downtime by over 60% compared to traditional welding methods.

Stepwise tightening to specified torque (typically 8-12 N·m) using a torque wrench eliminates the need for specialized welding equipment, making it suitable for high-altitude or fire/explosion-proof environments. For instance, in nuclear power plant cooling circuit installations, VCR joints eliminate heat-affected zones from welding, ensuring system safety.

Connects vacuum deposition equipment to specialty gas pipelines, maintaining ultra-high vacuum environments (10⁻⁹ mbar) to ensure uniform film deposition; prevents high-purity gas leaks during ion implantation processes that could reduce chip yield.

Withstands cryogenic shocks and high-pressure combustion of liquid oxygen/kerosene during rocket engine testing, guaranteeing zero fuel leakage; connects satellite vacuum chambers to sensors, providing stable environments for thermal vacuum testing.

Resists radiation and corrosion in nuclear reactor cooling systems, ensuring safe high-temperature, high-pressure water circulation; connects liquid helium circulation lines in MRI equipment, maintaining the 4.2K cryogenic temperature required for superconducting magnets.

Distinguish between imperial (1/8“, 1/4”) and metric (3mm, 8mm) pipe diameters to prevent leakage from cross-use; identify pipe thread types (NPT/PT) to avoid improper tightening or disassembly difficulties.

Choose nickel gaskets for high-temperature applications and Hastelloy gaskets for chemically corrosive environments. Specify retained (claw-type) or nonretained gaskets when ordering; retained types are suitable for vibrating conditions.

Use a torque wrench for stepwise tightening to prevent gasket distortion from over-tightening.

For high-purity applications, operate in a clean environment wearing lint-free gloves to prevent scratching pipe end faces.

Regularly inspect gasket aging; replace every 12 months or immediately after disassembly.

From nanoscale manufacturing in chip factories to extreme environment testing in rocket engines, VCR fittings underpin modern technology's precision operations with their “zero leakage” capability. Their design philosophy—achieving permanent sealing through elastic deformation of metal—embodies both the simplicity of engineering aesthetics and the depth of materials science. As semiconductor processes advance below 3nm and space exploration ventures deeper into the cosmos, VCR fittings will continue to safeguard every inch of piping in high-precision fields as the “invisible champions.”