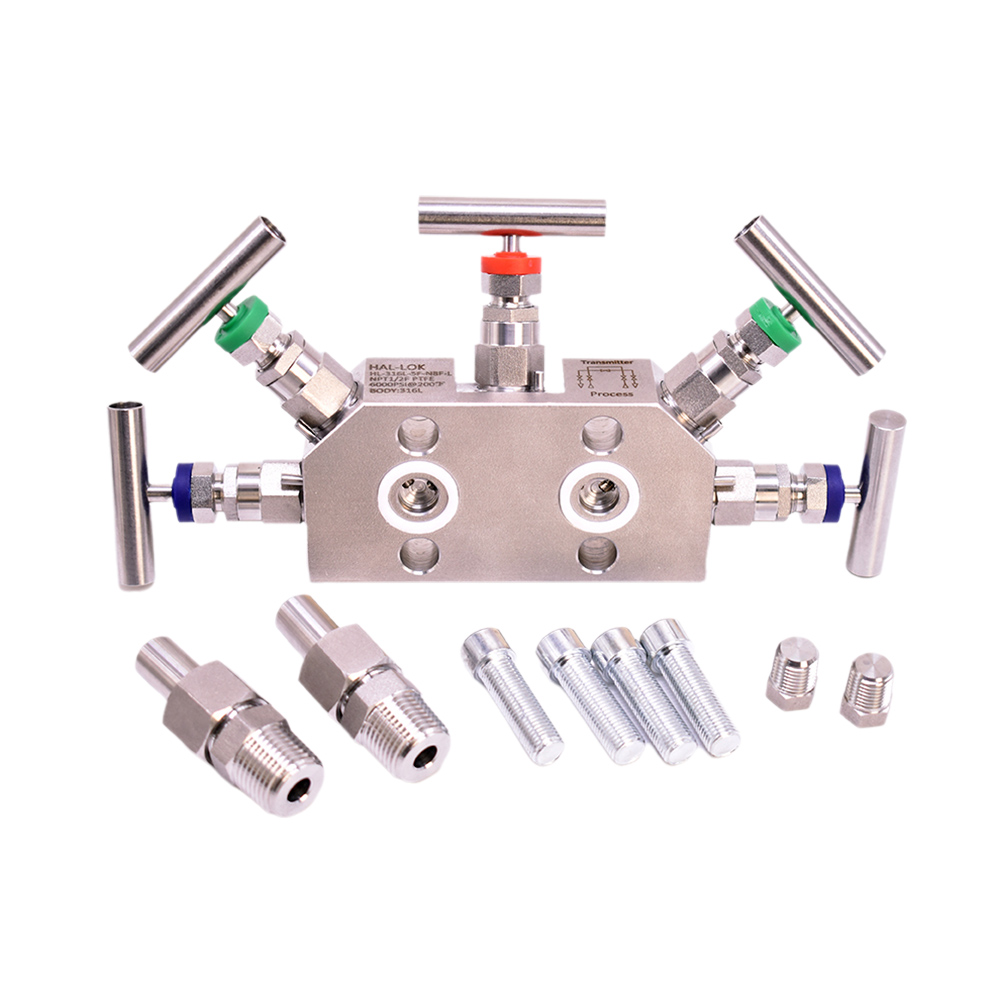

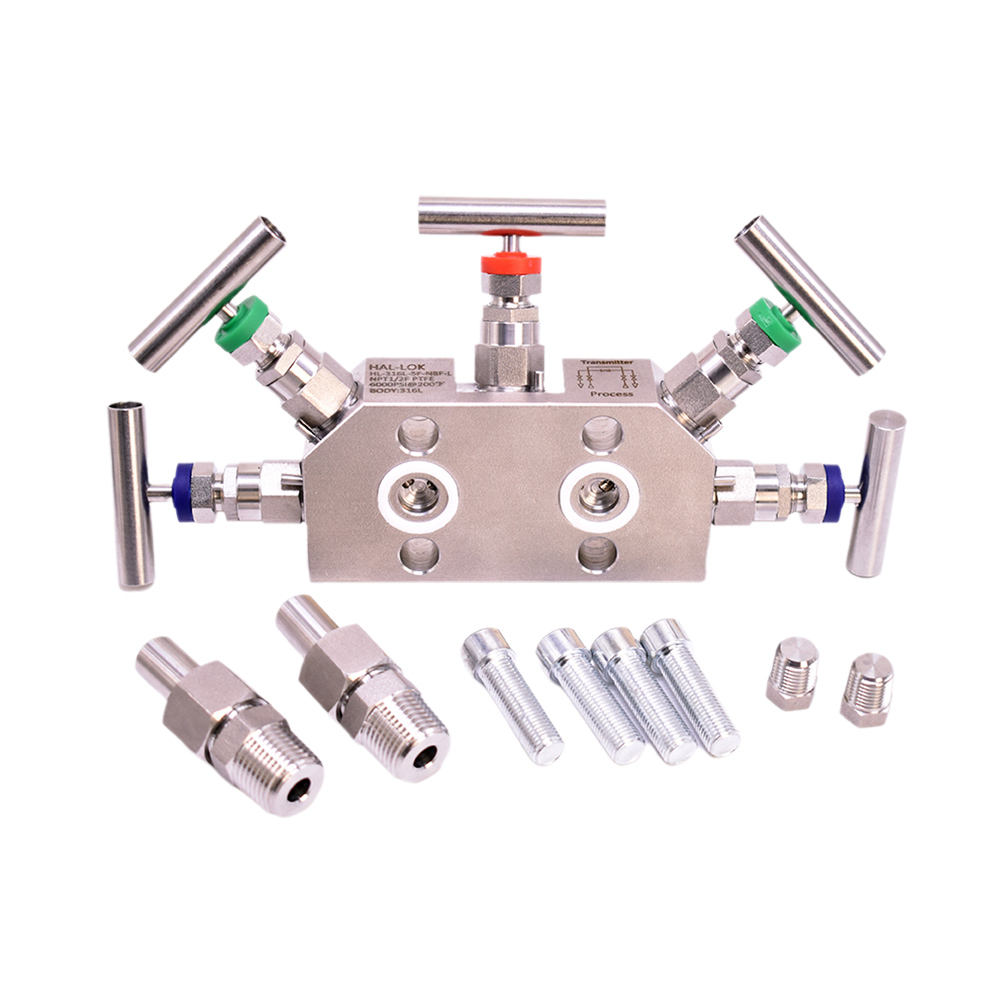

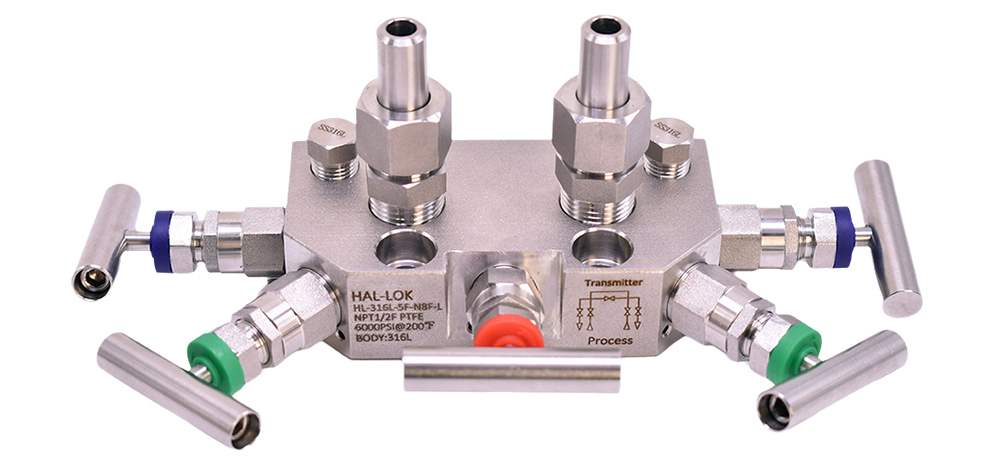

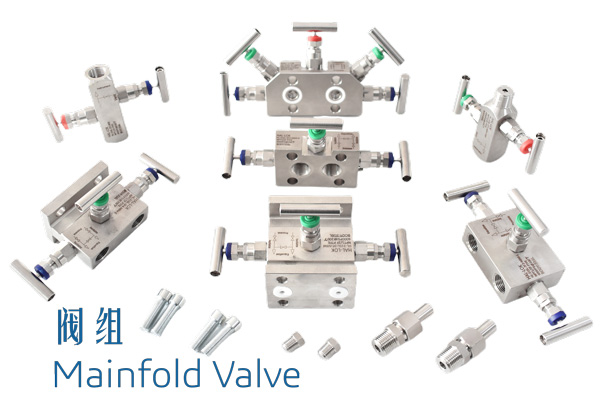

Valve manifolds are highly integrated fluid control system components designed to optimize pipeline layouts, simplify installation, and enhance system reliability. By consolidating multiple valves, instruments, and connection ports onto a compact valve block, they reduce leak points while improving the efficiency and safety of media distribution. Applications Industrial Gas Control: Centralized gas supply, flow distribution regulation, and pressure balancing. Process Instrumentation Systems: Media distribution for pressure/flow measurement lines. Hydraulic and Pneumatic Systems: Directional and pressure control for multiple actuators. Laboratory and Analytical Equipment: High-precision fluid management to prevent cross-contamination. |  |

| Valve Manifold Features: Modular Design: Supports multi-channel configurations (e.g., 2-valve, 5-valve, 8-valve) for flexible adaptation to diverse process requirements. High-Strength Materials: Typically constructed from 316 stainless steel, brass, or specialty alloys, suitable for high-pressure, corrosive, or high-purity media environments. Multi-functional Interfaces: Integrated ports for venting, equalizing, and relief facilitate system commissioning and maintenance. Low-Leak Seals: Utilizes metal seals or high-performance elastomers to ensure long-term stable operation and compliance with industry leakage standards. Diverse Actuation Options: Supports manual, pneumatic, or electric operation to meet automation control requirements. |